PEM Water Electrolysis Hydrogen Production System

High-purity hydrogen • Rapid response • Safe and reliable • Modular design

H₂ outlet pressure: 1.6 MPa, 3 MPa (16 bar, 30 bar)

H₂ purity: 99.999% (with hydrogen purification)

Operating range: (10~100)%

DC power consumption: 4.5 kWh/Nm³

Product Introduction

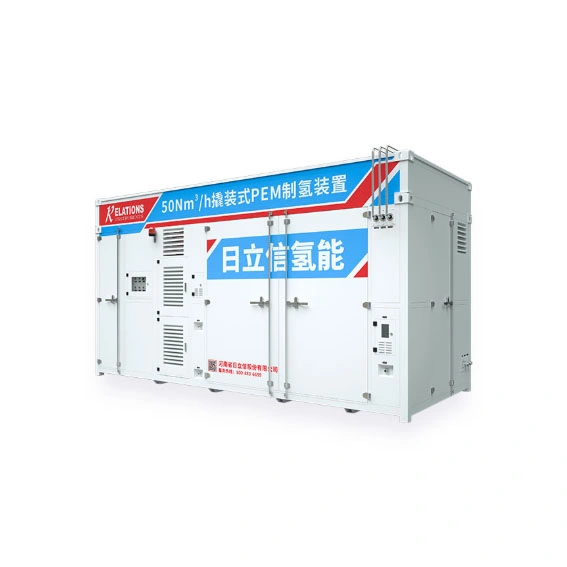

The PEM pure water electrolysis hydrogen production system is a high – efficiency, energy – saving and green hydrogen production equipment independently designed and developed by our company. This equipment includes multiple modules such as the power supply unit, pure water unit, control unit, electrolysis unit, cooling unit, purification unit, and main unit. Among them, the purification unit adopts TSA purification technology, and the deoxygenation device and water removal device remove trace amounts of oxygen and moisture at the hydrogen side of the electrolytic cell to ensure the hydrogen purity and humidity requirements and meet the on – site high – purity hydrogen output requirements of users. The single – set hydrogen production capacity of the system can be selected from various scales ranging from (0.5 – 200) Nm³/h, and the hydrogen purity reaches 99.999%.

Main Features

1. High hydrogen purity: The hydrogen purity reaches 99.999%. No additional purification treatment is required, and it can be directly used in fuel cells or other occasions with high requirements for hydrogen purity.

2. Quick response: The PEM pure water electrolysis hydrogen production system can start and stop quickly, has good adaptability to load changes, and is suitable for combination with renewable energy sources, especially intermittent or highly volatile energy sources such as wind energy and solar energy.

3. Safe and reliable: It adopts a partitioned explosion – proof design and is equipped with a complete fire alarm safety system. The nuclear – power – grade integral welding process is used to reduce leakage points and ensure the safe operation of the product.

4. Modular design: The PEM pure water electrolysis hydrogen production system adopts a modular design, which is convenient for expansion according to user needs and also convenient for maintenance and replacement.

5. Compact structure: It adopts a skid – mounted design, which is convenient for short – distance movement and has a small footprint.

6. Easy operation: The PEM pure water electrolysis hydrogen production system adopts a one – key start design, with a high degree of system automation, reducing the complexity of manual operation.

7. Green and environmentally friendly: The PEM water electrolysis hydrogen production process does not produce harmful emissions. It is a clean hydrogen production method that helps to achieve carbon neutrality.

8. Long service life: The proton exchange membrane and catalyst used in the PEM electrolytic cell usually have a long service life, which can ensure the stable operation of the system for a long time and requires long – term maintenance – free.

Product Parameters

|

For Research & Education |

|

|

Parameter Name |

Parameter Value |

|

Model Number |

RHP-H-0.5、RHP-H-1、RHP-H-2 |

|

Technology |

PEM water electrolysis |

|

Hydrogen Production |

0.5Nm³/h、1Nm³/h、2Nm³/h (8L/min、16L/min、33L/min) |

|

H₂ Outlet Pressure |

1.6MPa、3MPa (16bar、30bar) |

|

H₂ Purity |

99.999% (with hydrogen purification) |

|

Operating Range |

(10~100) % |

|

DC Power Consumption |

4.5kWh/Nm³ |

|

PEM System Dimensions |

1200×800×1800 mm (L×W×H) |

|

Control System Dimensions |

800×600×1800 mm (L×W×H) |

|

For Industrial Sites |

|

|

Parameter Name |

Parameter Value |

|

Model Number |

RHP-H-5、RHP-H-10 |

|

Technology |

PEM water electrolysis |

|

Hydrogen Production |

5Nm³/h、10Nm³/h |

|

H₂ Outlet Pressure |

1.6MPa、3MPa (16bar、30bar) |

|

H₂ Purity |

99.999% (with hydrogen purification) |

|

Operating Range |

(10~100) % |

|

DC Power Consumption |

4.5kWh/Nm³ |

|

Enclosure Dimensions |

2400×1800×2000 mm (L×W×H) |

|

For Large Low-Carbon Parks |

|

|

Parameter Name |

Parameter Value |

|

Model Number |

Custom PEM water electrolysis systems |

|

Hydrogen Production |

100Nm³/h、200Nm³/h |

|

H₂ Outlet Pressure |

1.6MPa、3MPa (16bar、30bar) |

|

H₂ Purity |

99.999% (with hydrogen purification) |

|

Operating Range |

(10~100) % |

|

DC Power Consumption |

4.5kWh/Nm³ |

|

PEM System Dimensions |

40-foot standard container: 12000×2400×2600 mm (L×W×H) |

|

Control System Dimensions |

20-foot standard container: 6000×2400×2600 mm (L×W×H) |

.webp)